Technology :

laser cut :

While designing the manufacturing and production process regarding the construction of material transfer chains and according to the type of internal needs (batch and custom production according to the needs of different factories), for the first time in Iran, we used the new laser technology in the field of cutting chain link parts with The highest quality.

In this method, due to the small cross-sectional area of the laser beam, high thermal concentration and high cutting speed, the thermal bond stress is very low compared to other sheet cutting methods, and also the so-called heat affected area (HAZ) is much more limited. It is also destroyed by normalizing heat treatment cycle up to 98%.

Also, during laser cutting, step holes are created on the links. These holes, which make up the pitch distance of the chain, are one of the most important parameters of a chain. The tolerance of the step distance of these holes in the laser method is about 0.05 mm, which can only be achieved with this method while respecting the principle of repeatability and accuracy.

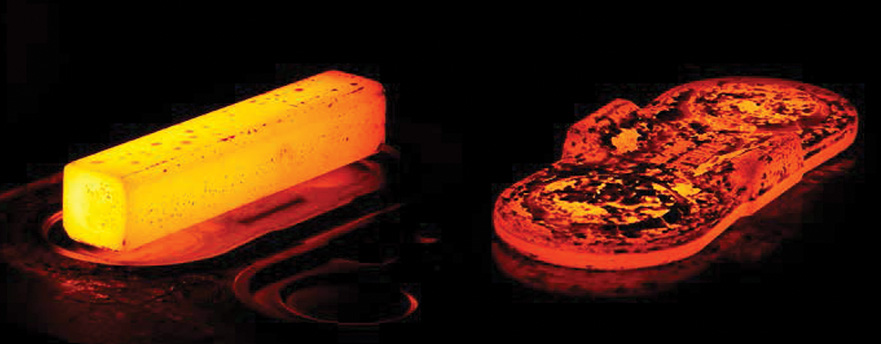

Stressing cycles: eliminating residual stresses

Volumetric and induction heat treatment of parts

Surface hardness

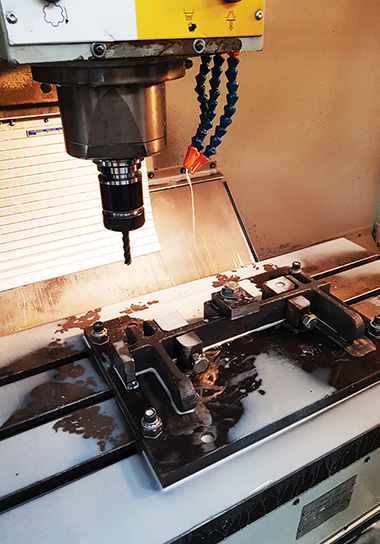

Machining parts by turning, milling and CNC drilling

Grinding parts with Russian Centerless: increasing the smoothness of the surface and measuring the parts

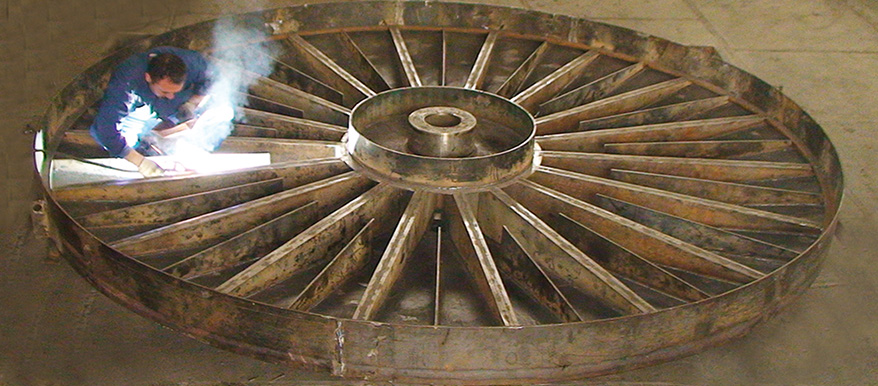

Assembling the chains in the form of pressing adaptations using the hydraulic pressing method

Technology / Process